Polyurethane Panel Core Comparison

Polyurethane Panel and EPS Panel Core Comparison

Why does SIP Supply use polyurethane rather than polystyrene?

SIP Supply chooses to use polyurethane foam insulation instead of expanded polystyrene (EPS) for several reasons in our Polyurethane Panel Core Comparison.

Polyurethane Panel Core Comparison

Firstly,

Polyurethane is a far better insulator. SIP polyurethane foam as a panel core comparison has a stable R-value of R-7 per inch of thickness, versus R-4 for EPS. This means that you can achieve R-28 with 4.5-inch walls. EPS-insulated walls would have to be nearly twice as thick to achieve the same R-value.

Secondly,

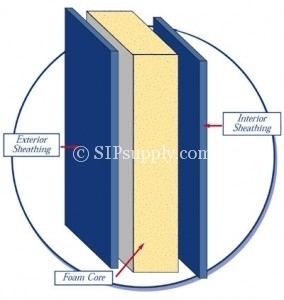

When polyurethane foam is injected into panels, the polyurethane panels are stronger than EPS panels. While the EPS is simply glued onto the substrates, injected polyurethane foam adheres and bonds to every surface (substrates, top-plates, splines, cam-locks, electrical boxes, etc.), and then becomes rigid. Polyurethane panels can withstand higher compression (or axial), transverse (or flexural), and racking loads.

Thirdly,

Polyurethane has better fire in a panel core comparison, flame, and smoke characteristics. Polyurethane does not melt at any temperature. It will withstand constant service temperatures up to 180-degrees Fahrenheit and will not char up to 275-degrees Fahrenheit.

Lastly,

Polyurethane panels allows the optional use of cam-locks, embedded into the foam. This saves labor in the field and makes strong panel connections. Cam-locks cannot be embedded into EPS. Simply put, polyurethane foam is a superior product for structural insulated panels.

PUR Fact: : A strong and durable bond exists between foam and skins. Heat and pressure created by the chemical reaction of the expanding polyurethane foam forces complete adhesion of the foam core to the skins.